Penyebaran Pengetahuan Tentang Panduan Linier

Nov 21, 2025

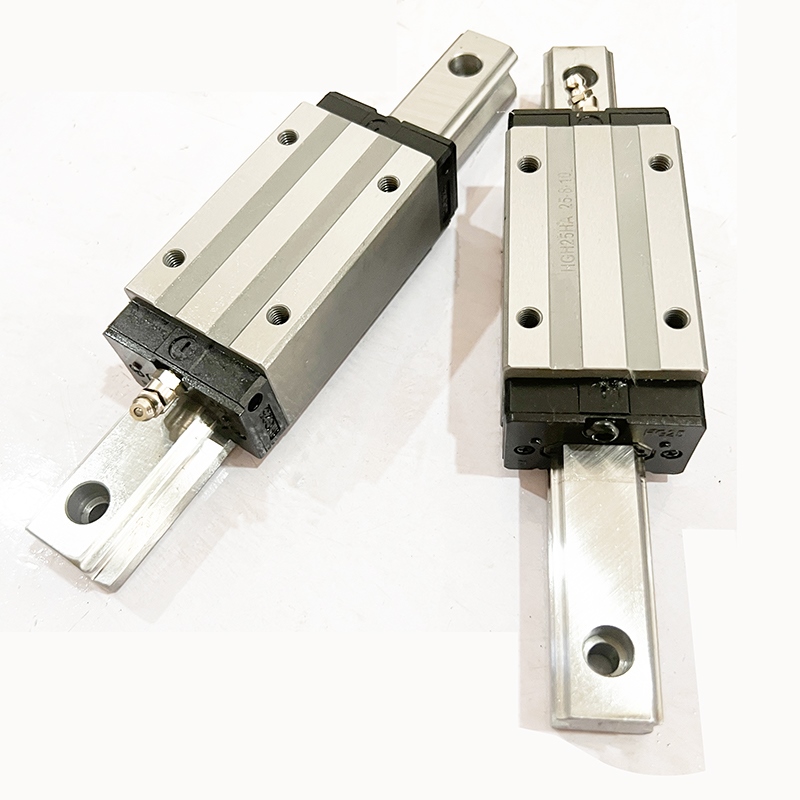

【Pemandu linier】Dapat dikategorikan menjadi pemandu linier bola, pemandu linier rol, dan pemandu linier roda. Pemandu ini digunakan untuk menopang dan memandu bagian yang bergerak, memungkinkan bagian tersebut melakukan gerakan linier bolak-balik dalam arah tertentu. Berdasarkan sifat gesekannya, pemandu gerak linier dapat diklasifikasikan menjadi pemandu gesekan geser, pemandu gesekan gelinding, pemandu gesekan elastis, dan pemandu gesekan fluida. 1. Definisi: Pemandu linier, juga dikenal sebagai rel linier, rel geser, atau pemandu linier, digunakan dalam aplikasi gerakan bolak-balik linier dan dapat menahan torsi dalam jumlah tertentu, sehingga mencapai gerakan linier presisi tinggi di bawah beban tinggi. 2. Fungsi: Fungsi pemandu linier adalah untuk menopang dan memandu bagian-bagian yang bergerak, sehingga memungkinkan bagian-bagian tersebut melakukan gerakan linier bolak-balik dalam arah tertentu. Bantalan linier terutama digunakan pada mesin otomatis, seperti mesin perkakas impor Jerman, mesin pembengkok, dan mesin las laser. Tentu saja, bantalan linier dan poros linier digunakan bersamaan. Pemandu linier terutama digunakan pada struktur mekanik dengan persyaratan presisi tinggi. Elemen bergerak dan stasioner dari pemandu linier tidak memerlukan media perantara; sebagai gantinya, digunakan bola baja yang bergulir. 3. Prinsip Kerja: Dapat dipahami sebagai pemandu bergulir, di mana bola-bola baja terus menerus bergulir dan bersirkulasi antara slider dan rel pemandu, memungkinkan platform beban bergerak dengan mudah dan linier sepanjang rel pemandu dengan presisi tinggi. Hal ini mengurangi koefisien gesekan hingga seperlima puluh dari pemandu geser tradisional, sehingga dengan mudah mencapai akurasi pemosisian yang sangat tinggi. Desain unit ujung antara slider dan rel pemandu memungkinkan rel pemandu linier untuk secara simultan menahan beban ke segala arah (atas, bawah, kiri, dan kanan). Sistem resirkulasi yang dipatenkan dan desain struktural yang disederhanakan membuat Rel pemandu linier HIWIN Memiliki pergerakan yang lebih halus dan lebih sedikit kebisingan. Slider mengubah gerakan dari kurva menjadi garis lurus. Seperti rel pemandu planar, rel pemandu linier memiliki dua komponen dasar: komponen tetap yang berfungsi sebagai pemandu, dan komponen bergerak. Karena rel pemandu linier merupakan komponen standar, bagi produsen mesin perkakas, satu-satunya tugas adalah membuat bidang pemasangan dan menyesuaikan paralelisme rel pemandu. Rel pemandu, yang berfungsi sebagai pemandu, terbuat dari baja yang dikeraskan dan digiling dengan presisi sebelum ditempatkan pada bidang pemasangan. Misalnya, sistem rel pemandu yang menahan gaya linier dan momen puntir sangat berbeda desainnya dari rel pemandu yang hanya menahan gaya linier. Seiring waktu, bola-bola baja mulai aus, melemahkan beban awal yang bekerja padanya dan mengurangi akurasi gerakan bagian kerja mesin perkakas. Untuk mempertahankan akurasi awal, penyangga rel pemandu, atau bahkan rel pemandu itu sendiri, harus diganti. Jika sistem rel pemandu sudah memiliki beban awal, dan akurasi sistem telah hilang, satu-satunya solusi adalah mengganti elemen penggulir. Sistem rel pemandu dirancang untuk memaksimalkan area kontak antara elemen tetap dan elemen bergerak. Hal ini tidak hanya meningkatkan kapasitas menahan beban sistem, tetapi juga memungkinkan sistem untuk menahan gaya benturan yang dihasilkan oleh pemotongan yang terputus-putus atau berat, mendistribusikan gaya secara luas dan memperluas area menahan beban. Untuk mencapai hal ini, sistem rel pemandu menggunakan berbagai bentuk alur, dengan dua jenis representatif: alur Gotik (lengkungan runcing), yang merupakan perpanjangan dari setengah lingkaran dengan titik kontak di puncaknya; dan alur berbentuk busur, yang memiliki tujuan yang sama. Terlepas dari bentuk strukturnya, tujuannya sama: untuk memaksimalkan radius kontak bola baja yang bergulir dengan rel pemandu (elemen tetap). Faktor kunci yang menentukan karakteristik kinerja sistem adalah bagaimana elemen yang bergulir bersentuhan dengan rel pemandu. 4. Bidang Aplikasi: ① Pemandu linier terutama digunakan pada mesin otomatis, seperti mesin perkakas impor Jerman, mesin pembengkok, mesin las laser, dll. Pemandu linier dan poros linier digunakan secara bersamaan. ② Pemandu linier terutama digunakan dalam struktur mekanis dengan persyaratan presisi tinggi. Komponen bergerak dan tetap dari pemandu linier tidak menggunakan media perantara, melainkan bola baja gelinding. Hal ini karena bola baja gelinding cocok untuk gerakan kecepatan tinggi, memiliki koefisien gesekan rendah, dan sensitivitas tinggi, memenuhi persyaratan kerja bagian yang bergerak, seperti pemegang alat dan luncuran pada mesin perkakas. Jika gaya yang bekerja pada bola baja terlalu besar, atau waktu pramuat terlalu lama, hal itu akan meningkatkan hambatan gerakan penyangga. 5. Tindakan Pencegahan Penggunaan: Mencegah Karat: Saat menangani rel linier secara langsung dengan tangan, cuci bersih keringat dan oleskan minyak mineral berkualitas tinggi sebelum menanganinya. Berikan perhatian khusus pada pencegahan karat selama musim hujan dan musim panas. Jaga Kebersihan Lingkungan: Jaga kebersihan rel linier dan lingkungan sekitarnya. Bahkan partikel debu kecil yang tidak terlihat oleh mata telanjang yang masuk ke dalam rel akan meningkatkan keausan, getaran, dan kebisingan. Pemasangan membutuhkan perhatian yang cermat. Rel linier harus dipasang dengan sangat hati-hati. Benturan keras, pemukulan langsung, dan transmisi tekanan melalui elemen penggulir dilarang keras. Alat pemasangan yang tepat sangat penting. Gunakan alat khusus jika memungkinkan, hindari penggunaan kain atau bahan berserat pendek. 6. Membersihkan Pemandu: Sebagai komponen inti peralatan, pemandu dan poros linier berfungsi sebagai pemandu dan penopang. Untuk memastikan akurasi pemesinan yang tinggi, pemandu dan poros linier harus memiliki presisi pemandu yang tinggi dan stabilitas gerakan yang baik. Selama pengoperasian, benda kerja menghasilkan sejumlah besar debu dan asap korosif. Akumulasi debu dan asap ini dalam jangka panjang pada permukaan pemandu dan poros linier secara signifikan memengaruhi akurasi pemesinan dan dapat membentuk lubang, memperpendek umur peralatan. Untuk memastikan pengoperasian mesin yang stabil dan kualitas produk, perawatan rutin pemandu dan poros linier sangat penting. Catatan: Untuk membersihkan pemandu, siapkan kain katun kering dan oli pelumas. Pemandu mesin ukir dibagi menjadi pemandu linier dan pemandu rol. Membersihkan rel pemandu linier: Pertama, pindahkan kepala laser ke paling kanan (atau kiri) untuk menemukan rel pemandu linier. Lap dengan kain katun kering hingga mengkilap dan bebas debu. Tambahkan sedikit pelumas (oli mesin jahit dapat diterima; jangan gunakan oli mesin). Gerakkan kepala laser perlahan ke kiri dan ke kanan beberapa kali untuk mendistribusikan pelumas secara merata. Membersihkan rel pemandu rol: Pindahkan balok melintang ke bagian dalam, buka penutup ujung di kedua sisi mesin, temukan rel pemandu, dan bersihkan area kontak antara rel pemandu dan rol dengan kain katun kering. Kemudian gerakkan balok melintang dan bersihkan area yang tersisa. 7. Prospek Pengembangan: Dengan terus berkembangnya industri seperti energi, komunikasi data, transportasi kereta api perkotaan, otomotif, dan pembuatan kapal, permintaan akan rel pemandu linier akan tumbuh pesat. Industri rel pemandu linier memiliki potensi pengembangan yang sangat besar di masa depan. 【Blok Geser】Material blok geser itu sendiri memiliki kekerasan dan ketahanan aus yang sesuai, cukup untuk menahan gesekan gerakan. Kekerasan bagian rongga atau inti pada blok geser harus sama dengan bagian lain dari rongga dan inti cetakan.1. Peralatan Proses Industri: Cetakan merupakan peralatan proses penting untuk memproduksi berbagai produk industri. Dengan perkembangan pesat industri plastik dan penerapan produk plastik yang luas di industri kedirgantaraan, elektronik, permesinan, pembuatan kapal, dan otomotif, persyaratan untuk cetakan menjadi semakin ketat. Metode desain cetakan tradisional tidak lagi memadai. Dibandingkan dengan desain cetakan tradisional, teknologi Computer-Aided Engineering (CAE) menawarkan keunggulan signifikan dalam meningkatkan produktivitas, memastikan kualitas produk, mengurangi biaya, dan mengurangi intensitas kerja. 2. Aplikasi: Digunakan secara luas dalam peralatan penyemprotan, mesin perkakas CNC, pusat permesinan, elektronik, mesin otomatis, mesin tekstil, otomotif, perangkat medis, mesin cetak, mesin pengemasan, mesin pengolahan kayu, pembuatan cetakan, dan banyak bidang lainnya. Jika Anda memiliki pertanyaan terkait hal ini, pakar produk kami dengan senang hati akan menjawabnya! Tim teknik kami akan dengan senang hati menjawab pertanyaan teknis Anda tentang aplikasi produk kami sesegera mungkin. Artikel ini disusun dari sumber daring untuk tujuan penyebaran informasi lebih lanjut. Jika melanggar hak Anda, silakan hubungi kami untuk penghapusan. Untuk informasi tentang sekrup ulir/rel pemandu/slider/spindel/perkakas mesin, jangan ragu untuk menghubungi kami.

JARINGAN DIDUKUNG

JARINGAN DIDUKUNG